What is Turbine Inlet Chilling?

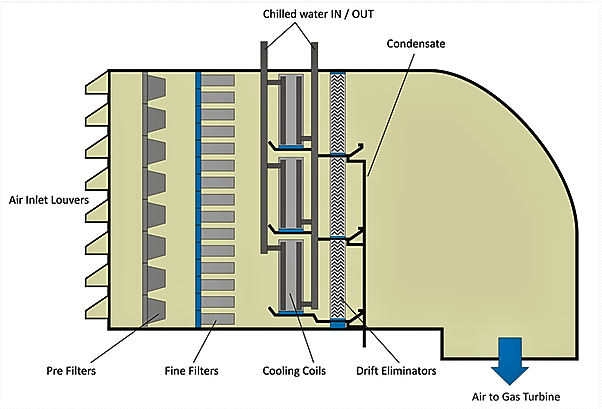

Turbine Inlet Chilling (TIC) is a system of air conditioning for a gas turbine to maximize the gas turbine output across all ambient conditions. This system can use water or forced air as the form of cooling.

Why Chill a Gas Turbine?

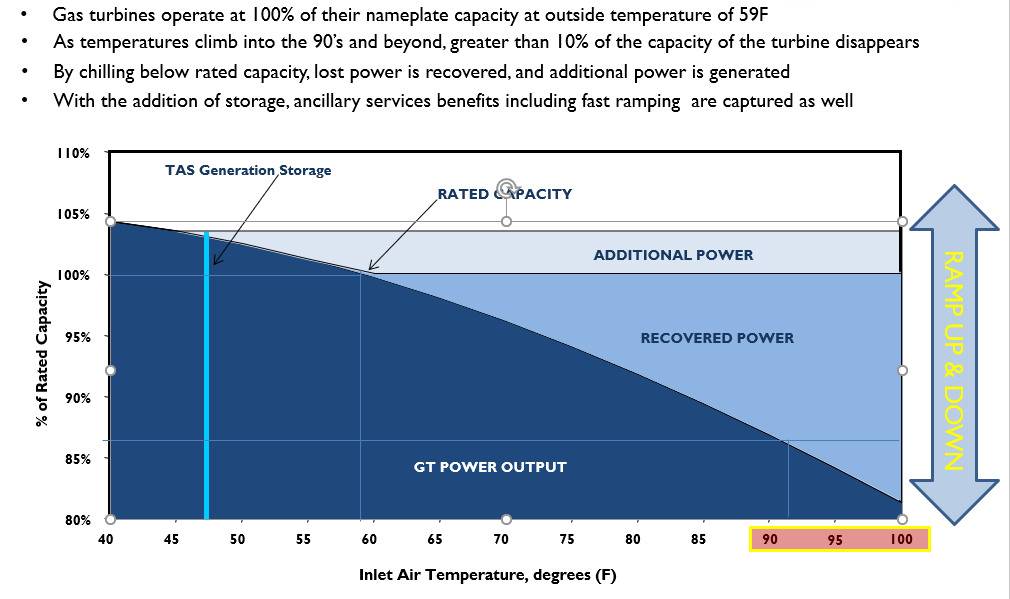

Gas turbines are designed to have optimum performance at ISO conditions (sea level, 59F/15C with 60% relative humidity). However, in hot and humid conditions, the gas turbine output decreases. Conditioning the air going into the gas turbine can recover the lost output.

What Can TIC Do for Your Gas Turbine?

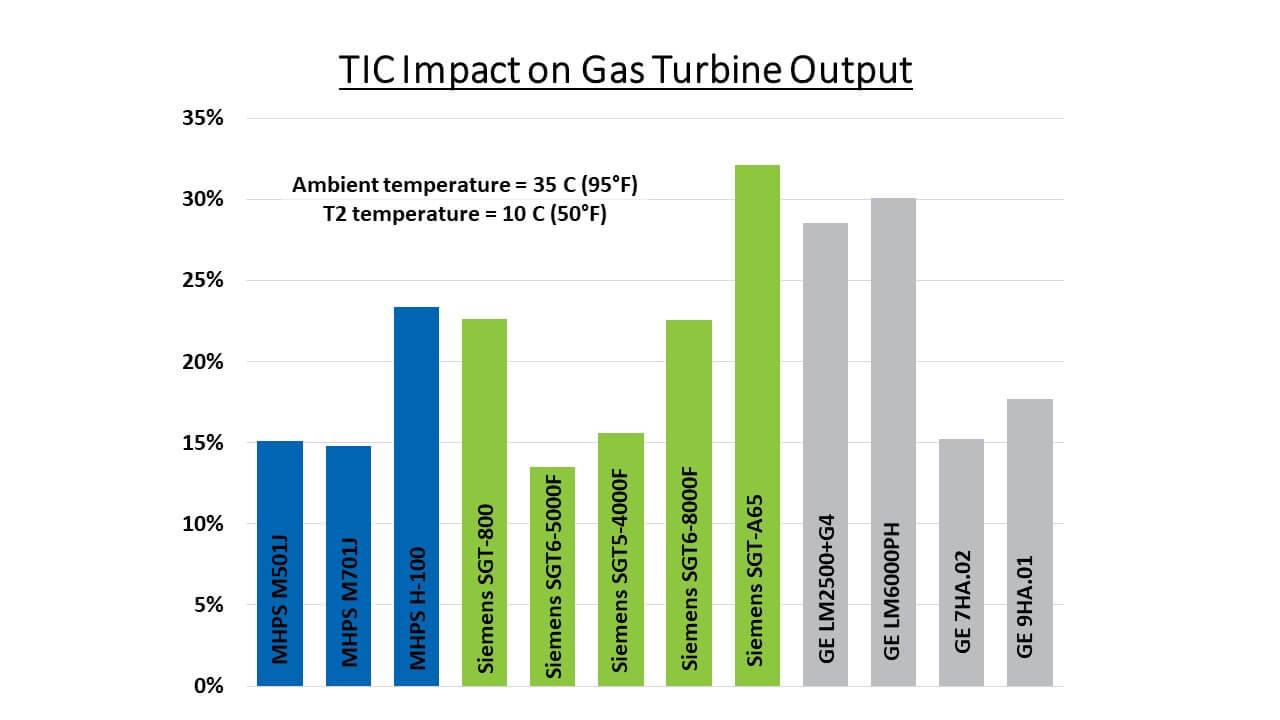

The overall benefit of TIC differs depending on the gas turbine model.

Key Features

- Series chillers allow TAS to extract 14% to 19% more refrigeration capacity out of commercial chillers while improving energy efficiency by 12 to 18%

- Series/counter flow chillers provide TAS to use dual chillers in any TIC application whether for use in an on-line or a Thermal Energy Storage (TES) application. Stored energy via a stratified thermal energy storage tank allows TAS to store energy in the form of chilled water.

- Variable turbine inlet temperature controls allow TAS to respond to rapid changes in grid load by rapidly varying the output of the gas turbine by adjusting the inlet turbine air temperature, which can supplement the variable generation caused by increased renewables.

- Variable speed pump for TIC/TES System allows TAS to use a variable speed pump for varying the flow of chilled water from the TES tank to the TIC cooling coil to modulate or maintain T2 turbine inlet air temperature set points.

- Filter house/coil module retrofit experience

- TES tank design and integration experience

- TIC/GS financial analysis and optimization tool and owner consultation expertise

- Turnkey TIC retrofit experience